Nylon Straight Cable Glands

Price 150 INR/ Piece

Nylon Straight Cable Glands Specification

- Operating Temperature

- -40C to +100C

- Locking Type

- Threaded with locknut

- Usage & Applications

- Industrial, outdoor, indoor, control panels, automation

- Insulation

- IP68 rated ingress protection

- Cable Type

- Round cable

- Rated Temperature

- -40C to +100C (short term up to +120C)

- Weight

- Varies with size (typically lightweight)

- Install Type

- Threaded mounting

- Diameter

- For cables from 3mm to 42mm (dependent on gland size)

- Tensile Strength

- High, suitable for securing cables under tension

- Features

- Waterproof, dustproof, corrosion resistant, high strength, easy installation

- Product Type

- Straight Cable Gland

- Length

- Customizable as per requirement

- Voltage

- Not applicable (for mechanical cable entry)

- Insulation Material

- Nylon (Polyamide PA66)

- Application

- Cable management, electrical junction box, machinery, industrial equipment

- Jacket Material

- Not applicable (product is a gland, not a cable)

- Storage Temperature

- -40C to +100C

- Connector Color

- Black / Grey / White

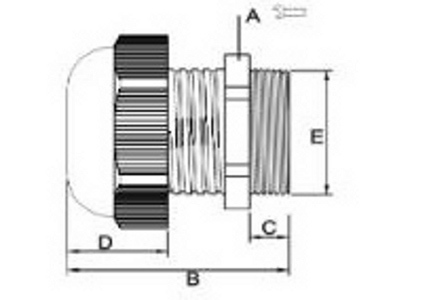

- Dimension (L*W*H)

- Dependent on gland size (available in M12 to M63 or as specified)

- Material

- Nylon (Polyamide PA66)

- Color

- Black, Grey, White

- Size

- Available in M12, M16, M20, M25, M32, M40, M50, M63, PG, and custom sizes

- Thread Type

- Metric (M), PG, NPT options available

- Temperature Resistance

- Continuous usage up to +100C, peaks to +120C

- Seal Material

- EPDM rubber sealing insert

- Protection Grade

- IP68 (waterproof and dustproof)

- Flammability Rating

- UL94 V-2

- Nut Material

- Nylon

- Installation Torque

- As per manufacturers specification

- Suitable Cable Diameter Range

- 3-42mm

- Panel Hole Size

- Corresponds to gland size (e.g. 12mm for M12, etc.)

Nylon Straight Cable Glands Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10-25 Days

About Nylon Straight Cable Glands

Nylon Straight Cable Glands

Powered by extreme domain experience, we are immensely involved in offering Nylon Cable Glands, Nylon Straight Cable Glands that are especially demanded for pipe connection purposes. This gamut of brass products is designed with precision making usage of the finest quality brass at par with the set international market standards. These Nylon Cable Glands and Nylon Straight Cable Glands are widely demanded in various sizes and shapes to fulfill clients' specific needs. Our clients can easily avail these cable glands from us at negotiable rates.

Features:

- Ruggedness

- Corrosion resistance

- Application specific design

- Durability

Technical Specification:

- Body : Polymide 6

- Sealing Washer : PVC

- Protection Class : Open

- Colour : Black only

- Cat. No : FC-NSCG-01

- Item Contents : Body, Cap, Nut, PVC Washer

Reliable Protection for Cables

These nylon cable glands ensure superior ingress protection with an IP68 rating, making them waterproof and dustproof. Their sturdy polyamide PA66 construction and EPDM sealing insert protect cables from environmental hazards and mechanical stress. Suitable for outdoor, industrial, and automation applications, they help maintain safety and reliability in electrical systems.

Versatile Installation Options

Available in Metric, PG, and NPT thread types, and sizes ranging from M12 to M63, these cable glands offer flexible installation for various cable diameters. The threaded mounting process with nylon locknut enables secure and stable fixation, simplifying installation across junction boxes, control panels, and machinery. Length and size can be customized upon request.

FAQs of Nylon Straight Cable Glands:

Q: How are Nylon Straight Cable Glands installed and secured to panels or equipment?

A: Nylon Straight Cable Glands are installed by threading them into a pre-drilled panel hole that matches the chosen gland size (for example, 12mm for M12). Secure fixation is achieved using the included nylon locknut, tightened as per the manufacturers specified installation torque. This ensures a robust, stable, and waterproof seal for cable entry.Q: What environments and applications are these glands best suited for?

A: With an IP68 rating, flammability UL94 V-2, and chemical-resistant nylon body, these cable glands excel in industrial, outdoor, indoor, and machinery applications. They are ideal for use in electrical junction boxes, control panels, and automation systems where protection against dust, water, and corrosion is crucial.Q: When should I choose Metric, PG, or NPT thread types for cable glands?

A: Metric (M), PG, and NPT thread types are chosen based on the installation location and compatibility with existing equipment. Metric threads are common in international and industrial settings, PG threads are typically used for legacy European installations, and NPT threads suit North American pipe fittings and machinery. Selection ensures precise fit and optimal sealing.Q: Where do customizable cable gland lengths and sizes add value?

A: Customizing cable gland lengths and sizes is valuable in projects with specific space constraints, unique panel configurations, or non-standard cable diameters. This flexibility enables secure cable management across diverse industrial, control panel, and automation environments, catering to installation requirements beyond standard dimensions.Q: What benefits does IP68 protection offer for cable management?

A: IP68 protection guarantees complete dustproof and waterproof sealing, safeguarding cables against environmental exposure, moisture, and contaminants. This extends system reliability, prevents electrical faults in harsh conditions, and supports long-term performance in outdoor or industrial applications.Q: How does the cable gland maintain safety at varying operating temperatures?

A: Constructed from high-strength nylon and EPDM rubber seal, these cable glands maintain their integrity and insulation properties from -40C up to +100C in continuous service, withstanding short-term peaks up to +120C. This makes them safe and effective for applications exposed to variable or elevated temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Glands Category

Flexible Cable Glands

Price 150 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Flexible Cable Gland

Size : Available in M10 to M63 or equivalent PG sizes

Material : Nylon (Polyamide PA6)

Color : Black, Grey

Metric Spiral Cable Glands

Price 150 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Metric Spiral Cable Gland

Size : Metric thread sizes (M12, M16, M20, M25, M32, M40, M50, M63, etc.)

Material : Polyamide (Nylon) PA6, seal: EPDM rubber

Color : Black, Grey, Light Grey

Spiral Cable Glands

Price 150 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Spiral Cable Gland

Size : M12, M16, M20, M25, M32, M40, etc.

Material : Polyamide (Nylon) PA6

Color : Black, Grey, White, or as per order

Nylon Flexible Cable Glands

Price 150 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Nylon Flexible Cable Gland

Size : M12 to M32, PG7 to PG21 (other sizes may be available)

Material : Polyamide 66 (Nylon)

Color : Grey, Black

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry