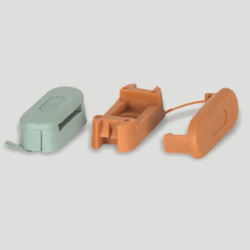

Polyamide pipe end fittings

Price 24 INR/ Piece

Polyamide pipe end fittings Specification

- Thread Type

- No Thread

- Yield Strength

- >50 MPa

- Sealing Type

- O-ring integrated

- Flexibility

- Semi-flexible

- Temperature Range

- -30C to +80C

- Coating Type

- Non-coated

- Tolerance

- 0.1 mm

- Connection Type

- Push Fit/Quick Connect

- Tensile Strength

- >55 MPa

- Diameter

- 12 mm

- Bend Radius

- 45 mm

- Product Type

- Pipe End Fittings

- Material

- Polyamide (PA)

- Connection

- Push Fit

- Shape

- Cylindrical

- Standard

- DIN EN ISO 1874-1

- Surface Treatment

- Smooth Finish

- Outer Diameter

- 12 mm

- Section Shape

- Round

- Length

- 40 mm

- Thickness

- 2 mm

- Color

- Black

- Usage

- Pipe-to-pipe joint

- Rated Pressure

- 10 bar

- Material Grade

- PA-6

- Application

- Industrial fluid systems

Polyamide pipe end fittings Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- NHAVA SHEVA

- Supply Ability

- 5000 Pieces Per Week

- Delivery Time

- 10-15 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- 100 NOS PER PKT

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About Polyamide pipe end fittings

Since our inception in 2001, we have successfully been engaged in manufacturing, exporting and supplying premium quality DC Tape Clip. Manufactured with the use of premium grade polyamide and advanced techniques, the provided clip is suitable for both bare as well as coated coper tape. Famous as an important component in electrical appliances, the provided clip is known for its remarkable features. Our clients can purchase this DC Tape Clip at highly competitive prices from us.

Features:

- Known for flawlessness

- Remarkable durability

- Compact size

- Supreme finish

DC Tape Clip

For bare & Coated copper tape

Material :- Polyamide

Product Code:- FCDTC-01-25 x 3 mm

FCDTC-02 - 30 x 6 mm

FCDTC-03 25 x 2.5 mm

Superior Chemical and Environmental Resistance

These polyamide pipe end fittings are crafted to deliver exceptional resistance against harsh chemicals, acids, and oils, ensuring reliable performance in demanding conditions. Their construction also offers robust UV protection and fire self-extinguishing properties, making them ideal for both indoor and outdoor industrial applications.

Effortless and Secure Installation

Designed with a push-fit or quick-connect mechanism, our fittings enable easy, manual installation without the need for special tools. Integrated O-rings ensure a leak-proof seal, while the cylindrical, smooth-finish body makes them compatible with polyamide and other plastic piping systems. Precision manufacturing guarantees consistent tolerance and minimal maintenance.

Engineered for Long-Term Performance

With a tested service life of up to 10 years, our pipe end fittings maintain strength and flexibility under pressure and varying temperatures. Each fitting is quality checked for leak-proof performance, supports a rated pressure of 10 bar, and is suitable for continuous operation between -30C and +80C, supporting reliable, long-term system integrity.

FAQs of Polyamide pipe end fittings:

Q: How are polyamide pipe end fittings installed?

A: The fittings feature a manual, tool-free push-fit connection, allowing quick and secure installation. Simply align the pipes and press them together to achieve a leak-proof seal, thanks to the integrated O-ring design.Q: What environments are these fittings suitable for?

A: These fittings are suitable for both indoor and outdoor use, as they offer excellent UV resistance, robust chemical stability, and self-extinguishing capabilities. Their durable build enables them to withstand a variety of industrial and environmental conditions.Q: When should polyamide fittings be used over metal alternatives?

A: Polyamide fittings are ideal when resistance to corrosive chemicals, low maintenance, and easy installation are priorities. They provide excellent compatibility with plastic pipes, weigh less than metal, and do not corrode, making them particularly useful in controlled fluid systems.Q: What is the main benefit of using these fittings in industrial fluid systems?

A: The main advantages include excellent chemical resistance, a secure leak-proof push-fit connection, low maintenance requirements, and a long service life under pressures up to 10 bar and temperatures ranging from -30C to +80C.Q: Are these pipe end fittings tested for leak-proof performance?

A: Yes, every fitting is 100% leak-tested during production to ensure they provide a secure, reliable joint that prevents fluid leakage in operation.Q: Can these fittings be used with pipes made from other plastics?

A: Yes, while specially designed for polyamide (PA) pipes, these fittings are also compatible with a variety of other plastic piping systems owing to their precise size, O-ring sealing, and push-fit design.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Gland & Adaptors Category

Flexible Conduit Pipe Gland

Price 24 INR / Piece

Minimum Order Quantity : 500 Pieces

Outer Diameter : 20 mm

Temperature Range : 20C to +100C

Surface Treatment : Other, Nickel Plated

Tolerance : 0.1 mm

Flexible corrugated Pipe adaptors

Price 24 INR / Piece

Minimum Order Quantity : 500 Pieces

Outer Diameter : 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 63 mm

Temperature Range : 20C to +85C

Surface Treatment : Other, Smooth

Tolerance : 0.10 mm

Corrugated Pipe Glands

Price 24 INR / Piece

Minimum Order Quantity : 500 Pieces

Outer Diameter : 20 mm

Temperature Range : 40C to +120C

Surface Treatment : Other, Smooth Finish

Tolerance : 0.2 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry