Spiral Wire Bind

Price 120 INR/ Piece

Spiral Wire Bind Specification

- Temperature

- Ambient Room Temperature

- Product Type

- Spiral Wire Bind

- Material

- Metal Wire

- Function

- Binding Sheets Together

- Usage

- Office, School and Printing

- Insulation Material

- None

- Color

- Black, White, Blue, Red, More Colors Available

- Diameter

- Diameter as per selected size (typically ranges from 6 mm to 38 mm)

- Application

- Document Binding

- Durability

- Long lasting and rust resistant

- Strength

- High tensile strength

- Shape

- Spiral / Coil

- Compatible Equipment

- Compatible with standard wire binding machines

- Customizable

- Available for size, color, length

- Binding Capacity

- Up to 250 Sheets (depends on spiral size)

- Industrial Use

- Book Binding, Catalogue Binding

- Minimum Order Quantity

- 100 Pieces

- Reusable

- No

- Lead Free

- Yes

- Finish

- Smooth

- Packing Type

- Polybag, Carton Box, Bundle

Spiral Wire Bind Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 2-10 Days

About Spiral Wire Bind

The provided Spiral Wire Bind is suitable for bunching of loose wire and cable. This wire is manufactured with high precision under the strict supervision of our adroit professionals using quality examined raw materials and sophisticated technology. Further, offered Spiral Wire Bind are made available in varied length and other related specifications at market leading prices within the estimated time span.

Features:

- Highly flexible

- Elevated durability

- Fine finish

- Excellent strength

Technical Specifications:

- Material : LDPE

- Spiral Wire Bind are suitable for bunching of loose wire and cable

Customizable for Every Need

Whether you require a unique size, color, or length, these spiral wire binds can be tailored to your specific requirements. Ideal for offices, schools, or large-scale printing projects, each coil offers flexibility and reliable performance, ensuring that all your binding tasks have a professional finish.

Exceptional Strength and Longevity

Manufactured from metal wire with high tensile strength, Spiral Wire Binds are designed to endure daily handling and frequent use. Their smooth, rust-resistant surface maintains integrity over time, making them a dependable solution for binding documents over extended periods.

Simple and Versatile Application

Easily compatible with standard wire binding machines, these spiral coils streamline the document-binding process. Their efficient design allows quick insertion and secure closure, making them an excellent choice for binding reports, booklets, catalogs, and manuals in any professional or educational setting.

FAQs of Spiral Wire Bind:

Q: How do I select the appropriate diameter for Spiral Wire Bind coils?

A: The diameter of the spiral wire should correspond to the thickness of the document you wish to bind. Typically, the coils are available from 6 mm to 38 mm, accommodating up to 250 sheets. Its recommended to slightly oversize to ensure smooth page turning.Q: What types of binding equipment are Spiral Wire Binds compatible with?

A: These spiral wire binds are compatible with most standard wire binding machines commonly used in offices, schools, and print shops, ensuring straightforward integration into your existing workflow.Q: When should I use metal spiral binding over other binding methods?

A: Metal spiral wire binding is preferred for projects requiring durability, strength, and a professional finish. It is particularly beneficial when binding documents that will be handled often, such as manuals, catalogs, and notebooks.Q: Where are Spiral Wire Binds commonly used?

A: Spiral wire binds find widespread application in offices, educational institutions, and printing houses. They are used for document binding, report preparation, catalog assembly, and bookmaking, among other publishing needs.Q: What is the process for binding documents with spiral wire?

A: To bind with a spiral wire, punch holes along the binding edge of the stacked sheets, insert the spiral wire, and close it securely using a compatible binding machine. The process is quick, efficient, and yields a secure, professional result.Q: Are custom sizes and colors available for Spiral Wire Binds?

A: Yes, these spirals can be customized in terms of size, color, and length to match your specific project and branding requirements. Common colors include black, white, blue, and red, with more options available upon request.Q: What are the benefits of using Spiral Wire Bind for document binding?

A: Spiral Wire Binds offer high tensile strength, long-lasting durability, and rust resistance. They maintain document integrity, enable easy page turns, and provide a polished look, making them ideal for professional and educational use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wires/Cables & Accessories Category

Line Tap

Price 300 INR / Piece

Minimum Order Quantity : 100 Pieces

Length : Varies by model, typically 3050mm

Product Type : Line Tap

Temperature : 10C to +80C

Application : Electrical power distribution, telecommunication

MCB Shorting Links

Price 120 INR / Piece

Minimum Order Quantity : 1000 Pieces

Length : Customized / Standard (varies as per model)

Product Type : MCB Shorting Links

Temperature : 10C to 90C

Application : Electric panel distribution, MCB busbar

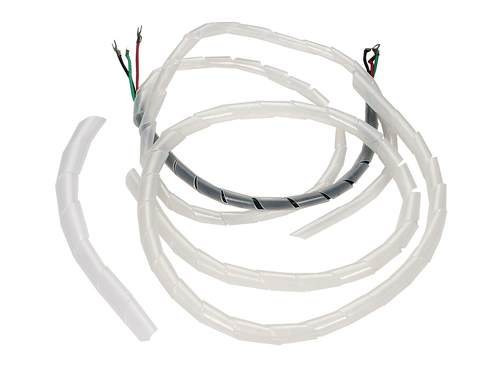

Spiral Wire Wrapping

Price 120 INR / Piece

Minimum Order Quantity : 1000 Pieces

Length : 10 m (standard lengths available in 5m, 10m, 20m)

Product Type : Spiral Wire Wrapping

Temperature : 20C to +60C

Application : Electronics, Electrical Panels, Industrial Equipment, Office Cables

Screw Mounting Tie Support

Price 120 INR / Piece

Minimum Order Quantity : 1000 Pieces

Length : Standard sizes available (e.g., 20mm, 25mm, 30mm)

Product Type : Screw Mounting Tie Support

Temperature : Up to 85C

Application : Electrical installations, panels, telecom racks, home wiring

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry